CO2 Removal Systems

Design, Evaluation and

Optimization

Mixed Amine Systems

including

Rigorous MDEA

Simulation

Design, Evaluation and

Optimization

Mixed Amine Systems

including

Rigorous MDEA

Simulation

Inquire CO2 Removal Systems

Design, Evaluation, Rating,

Optimization and Advanced

Technology Retrofit Services

Design, Evaluation, Rating,

Optimization and Advanced

Technology Retrofit Services

| CO2 Removal - Equipment Design, Evaluation and Optimization Including MDEA Based Systems - Rigorous Simulation Chem-Engineering Services supplies clients process engineering services for evaluating existing Mixed Amine CO2 Removal System operations, plant tuning for optimization of energy use, and retrofit designs to increase capacity and efficiency. |

| Mixed amine solvents have become popular World-Wide because of their high performance and reliability in removing Carbon Dioxide from Synthesis Gas streams. Process Engineering improvements for Mixed Amine CO2 Removal Systems are available from Chem-Engineering Services to increase plant capacity and/or reduce energy use by about 50 percent including: |

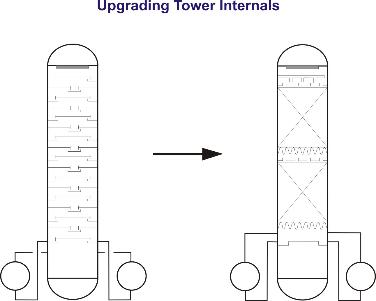

| Replacement of CO2 Absorber and CO2 Stripper internals |

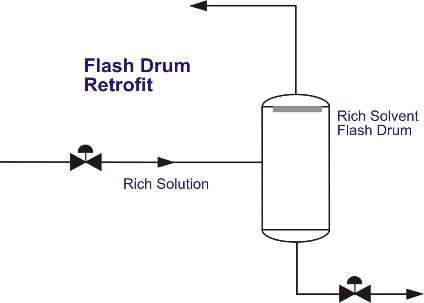

| Rich Solvent Flash Drums |

| Replacement Heat Exchangers - optimized for energy reduction |

| Rich Solvent Hydraulic Power Recovery Turbines |

| Conversion of Single Stage CO2 Removal Systems to Multi-Stage Systems Optimizing solvent composition and lean solution loading Replacement of existing pumps, turbines and related equipment with modern, high efficiency components Energy auditing and tuning of key process variables to increase production or reduce energy use |

Retrofit Existing CO2 Removal Systems to Low Energy Designs (Click here)

New MDEA Based CO2 Removal Process Simulation article (Click here)

For further information about Chem-Engineering Services process

engineering support for your plant site, contact:

engineering support for your plant site, contact:

| 1500 Glenmar Avenue Monroe, Louisiana 71201 USA Tel 318-387-5791 Fax 318-387-5791 e-mail glenn@chemengservices.com |

| E-Mail: |

Copyright © 2005-2016 Chem-Engineering Services. All Rights Reserved.